易格斯IGUS——Energy Chain能源链系统

5月2日易格斯CeMAT2011物流展会的会议中心召开了新闻发布会,重点介绍其E-Chain Systems:“Igus公司是能源拖链系统专家,每天拖链系统可产生38,000米长的链条来供应能源、数据和媒介,以实现快速和安全地移动物品。是目前世界范围应用最广泛的能源供应解决方案!”

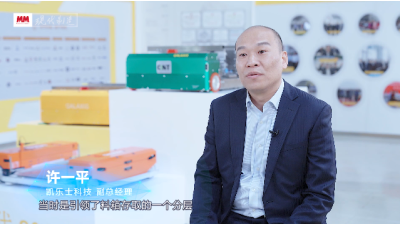

Mr. Harald Nehring, Vice President, Energy Chain Systems 和Mr. Andre Kluth M.A., Head of Corporate Communications在新闻发布会现场合影

Solve everything, with chains

igus at the "CeMAT": E-engineering on the Web,

a variety of products readily available from stock

At the "CeMAT in Hanover plastics technology expert igus GmbH of Cologne presented many innovations and improvements especially for intra-logistics. The company, a specialist in energy chain systems, produces around 38,000 metres every day, to supply energy, data and media, moving loads dynamically and with security. "Judging by existing figures," said CEO Frank Blase at a press conference, "our energy chain construction kit is the most popular solution for energy supply functions worldwide". With only a modular construction kit of chains, cables, and accessories – comprising over 70,000 parts – customers can perform almost any task, from a clean room to a concrete factory, from 800 m of travel to 3,000° rotations, from 10 g of accelerations to explosion-proof environments. Frank Blase: "Using maintenance-free plastic chains, all kinds of media can be connected without interruption". The company (2,000 employees, 310 million euros turnover) wants, among other things, to perfect the speed of delivery from stock. igus has its own branch offices in 28 countries around the globe, plus dealers in more than 35 other countries. Blase: "The goal must be: configured online in minutes, delivered in 24 hours or on the same day, assembled on site if required. With fully assembled systems, depending on the complexity, in a maximum of ten days, including a system warranty. In most cases," says Blase, "we can already do it". The 26 Internet tools currently at www.igus.eu play an important role in the igus trio of speed, durability and comfort, and all available free, with no need for registration. Users will find their customized solutions for energy supply, can configure the interior layout design for an entire factory, and can calculate product lifetimes precisely – for example, with "QuickLife", the world's only calculator of the lifetime of energy chains.

Storage and retrieval units go up quickly at 7 m/s

As a new standard for storage and retrieval devices (RGBs), construction- and crane-lifts, Harald Nehring, Division Manager for Energy Chain Systems, now presents the "guidelok slimline F" system. Nehring: "We have 25 years experience of supplying vertical systems to thousands of several thousand customers." With mast heights up to 50 metres, high speeds up to 7 m/s and accelerations up to 10 m/s2 the chain always remains safely on the track, and even with heavy lateral accelerations there is no swing-out, e.g. toward the normal area of operation. The new "guidelok slimline F" system for continuous energy chain applications does not require a closed channel trough or other elaborate, expensive housings. Instead, lightweight, slim plastic segments are mounted just every two metres, which saves up to 80 percent in costs for troughs.

Two automatically operated rockers are mounted on the chain and ensure quiet, smooth operation. The chain runs along the radius of the segment; the rocker is activated and the chain is fixed in place. The innovative locking levers are complemented by open guide rails made of reinforced plastic between the segments, which allows even greater dynamic loads.The first deliveries to well-known RBG manufacturers are already set for this week, Harald Nehring reported at the "CeMAT”.

Power, data and media, all connected

Power, data and media likewise all lead into one horizontal system, the so-called "micro flizz" from igus. In contrast to power rails, which only provide the power supply, a compact, closed system with the smallest energy chains can also provide such things as failure-free control signals and air. The system is also superior to the traditional standard busbar conductor systems, according to Harald Nehring, due to the interference-free and faster data transmission, for example with bus- or fiber optic cables. With "micro flizz", the upper and lower runs of the energy chain are separated from each other, so there is no friction. The chain is space-saving feature in a guiding channel that provides protection from dirt and dust, guided along a groove. Movable wings along the sides hold the chain securely in the channel: as the energy chain turns within the radius, it lies flat, so that the chain can leave the groove and roll gently. The assembled system for RBGs and indoor cranes allows accelerations up to 50 m/s2 and speeds up to 6 m/s.

Indoor cranes: 80 percent less assembly time

For quick and easy side-mounting on the crane carrier, igus presented at the "CeMAT" a new trough, which fits almost any standard crane carrier and thus eliminates obstructions. The one-piece steel trough (optional black-powder-coated stainless steel or, as a special model, in aluminium) greatly simplifies electrification. Special plastic holders fix the channel at a distance of 500 mm and have cable guides to insert the cables directly into the energy chain. By using integrated strain relief in the brackets, the well-mounted cables can be installed directly onto the crane carrier. For quick installation of the energy chain, there are pre-drilled patterns for the chain end brackets. Igus offers the new "fastguide" trough as a complete package for indoor cranes with the standard trough length of 2 m and with a robust "E2/000" energy chain and bend-resistant “Chainflex” cables. The new system reduces assembly time by 80 percent, according to the company.

Roller chains: 57 percent energy

The "P4.32" roller energy chain is ideal for applications in material flow with high travel speeds up to 10 m/s and large filling weights of up to 30 kg/m. The "P4" series, which is especially quiet and abrasion-resistant, is used particularly in crane design and in conveyor systems. The upper run rolls run through the rollers of the lower run, so they offset each other instead of rolling over one another, which further increases the lifetime of the chain. In addition, the division of the chain links with and without rollers is the same, so that the energy chain achieves extremely quiet and vibration-free operation. The tribologically optimised profile rollers are themselves securely integrated into the side panels. The use of roller energy chains also reduces the friction factor. Tests show that compared to sliding chain applications, so much less driving power is required that up to 57 percent of the energy can be saved, sufficient for smaller motors, and driver controllers, electronic frequency converters and mechanics.

Container cranes: travel 1,000 metres

The "P4.32" presented at the "CeMAT" is the smallest version of the "P4" family. More than ten years ago, with the development of the roller energy chain, igus developed a secure solution for energy and data transmission in crane design. igus energy chain systems have shown their strengths around the globe since then, in the most demanding crane operations in container- and bulk-handling. Recently, the 498th Ship-to-Shore crane was equipped with an energy chain from the Cologne company. There are also about a hundred goliath cranes and bulk material cranes. And in respect to RTGs and RMGs, the company has produced 3,500 chains in use worldwide. Harald Nehring: "The `P4' system, introduced three years ago, is a product with sufficient reserves for the fastest and largest presently feasible cranes." Long travel distances of up to 1,000 m are possible that are secure and reliable; the longest current route in the world with a plastic energy chain is 615 m at the Czech coalfield of Tusimice. Igus has also developed other milestones "around the chain". These range from floating cantilevers to compensate for lateral skew tolerances between the trolley or crane track and the chain systems, to the electronic power-monitoring "PPDS" for condition sensing, to “Chainflex” fibre optic cables which are flexible at a low temperature, for continuous-motion usage in chains at temperatures as low as -40°C.

Picture PM1311-01: igus GmbH, Cologne

New standard for storage and retrieval devices: the "guidelok slimline F" system from igus GmbH, Cologne, for mast heights up to 50 metres, high speeds of up to 7 m/s and accelerations of up to 10 m/s2. Vertical energy chain applications no longer require elaborate housings, like closed channel troughs.

Picture PM1311-02: igus GmbH, Cologne

Energy, data and media are connected in a compact system: the "micro flizz" from igus, Cologne is shown here on the assembly line for changing containers at a packaging factory for dry noodles.

Picture PM1311-03: igus GmbH, Cologne

Indoor cranes: The "fastguide" trough from igus, Cologne, presented at the "CeMAT", saves 80 percent of assembly time and greatly simplifies electrification. It adapts to almost any standard crane carrier.

Picture PM1311-04: igus GmbH, Cologne

Fast and quiet: the "P4.32" roller energy chain, with "Chainflex" cables from igus, Cologne, provides up to 57 percent energy savings; here it is used to supply a pallet truck for transport of materials in tobacco production.

Picture PM1311-05: igus GmbH, Cologne

Roller energy chains from igus, Cologne have demonstrated their strengths for over ten years worldwide, in container- and bulk-handling. The picture shows the rugged "P4" plastic energy chain system, installed on a dockside crane in Qingdao, China. The travel distance is 120 m, the speed 4 m/s; the required driving power can be reduced by up to 75 percent.

Picture PM1311-06: igus GmbH, Cologne

New: the compact, easy to install "Easy PPDS 2.0" condition monitoring system from igus, Cologne, for electronic power-monitoring on long energy chain travels.

获取更多评论